Powder coating

is one of the most popular forms of surface finish

At Foseko, we use proven products from reputable suppliers for painting, which are resistant to mechanical damage and corrosion.

Comprehensive powder coating process

Powder coating significantly “prolongs the life” of metal components that surround us in our daily lives. Every day, thriving factories and automotive companies supply products in which even the smallest detail is crucial. One of the factors contributing to their durability is the right protective coatings. That is why our mission is to create perfect powder coatings that effectively protect metal surfaces. All this so that your processes run smoothly and your final products serve their users for as long as possible.

You don’t have to wait weeks for your order to be processed

We are a state-of-the-art coating plant specialising in powder coating, combining many years of experience with advanced technologies to deliver the highest quality services in a short time. Our team of experts, automated processes and personalised approach to each customer guarantee not only precision and durability of coatings, but also fast turnaround of orders.

We focus on completing your order accurately and on time

Therefore, if you care about quality and efficient order processing, we are here for you.

Professional service

We have the space, resources, and time to focus on your project.

We are transparent

Come and visit our coating plant and learn more about our processes.

Modern solutions

We use innovative technologies from world leaders.

You have an overview of the whole process

We create detailed control charts, providing an insight into the production process.

We listen carefully and provide advice

We start by understanding your needs and always find the optimal solution.

Top quality powder coatings

We only use proven powder coatings from reputable manufacturers.

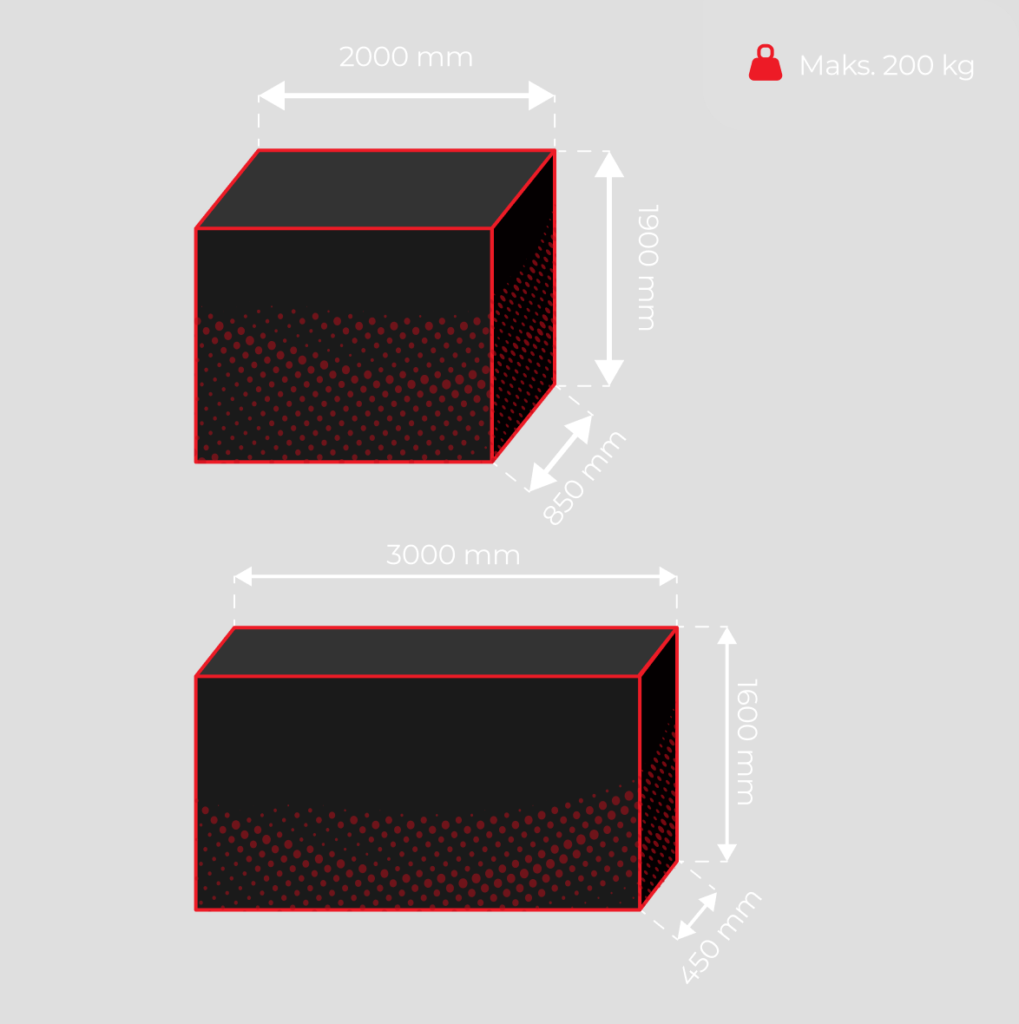

Standard dimensions of the structures we paint

Contact us regarding the dimensions and we will determine if we can fulfil your order. We have also painted larger structures, but this requires prior consultation.

From surface preparation to paint application

We offer high-tech powder coating services for all metal components and surface preparation: mechanical and chemical.

See how it works in practice

Powder coating is a process that requires precision — and you’ll find it in every layer with us.

Analysis and Planning

Every project begins with a thorough analysis of the client’s needs. Our team of experts carefully reviews specifications, discusses requirements, and plans each stage of the process. This is where we select the appropriate materials, prepare the equipment, and define the work schedule. Thanks to this approach, we can ensure not only the highest quality but also on-time delivery.

Production Preparation

The next step is the precise preparation of components for coating. Our experienced teams carefully hang each element, ensuring proper positioning. Every operation is carried out according to strict technical guidelines, which guarantees repeatability and top-quality results.

Chemical Pretreatment

The core stage is chemical surface pretreatment. This involves degreasing the parts and applying a conversion coating in the form of iron phosphates, which improves the adhesion of the coating and increases the corrosion resistance of the final products. Each part is treated individually, according to its characteristics and the client’s requirements.

See how it works in practice

Powder coating is a process that requires precision — and you’ll find it in every layer with us.

Analysis and Planning

Every project begins with a thorough analysis of the client’s needs. Our team of experts carefully reviews specifications, discusses requirements, and plans each stage of the process. This is where we select the appropriate materials, prepare the equipment, and define the work schedule. Thanks to this approach, we can ensure not only the highest quality but also on-time delivery.

Production Preparation

The next step is the precise preparation of components for coating. Our experienced teams carefully hang each element, ensuring proper positioning. Every operation is carried out according to strict technical guidelines, which guarantees repeatability and top-quality results.

Chemical Pretreatment

The core stage is chemical surface pretreatment. This involves degreasing the parts and applying a conversion coating in the form of iron phosphates, which improves the adhesion of the coating and increases the corrosion resistance of the final products. Each part is treated individually, according to its characteristics and the client’s requirements.

What services do we provide in our coating plant?

We paint metal components for individual customers as well as small and large companies.

Individual customer service

You can get your bike or even your fence painted with us. We carry out individual orders for our customers, with attention to every detail, even the smallest one.

Powder coating for production

We provide services for companies that have metal production and need a professional powder coating service. We adapt to your standards.

Support for larger companies

We carry out powder coating orders for companies that have a line at their premises but need support: in terms of quantity, time or size.

Abrasive blasting

Glass bead blasting and shotblasting are treatment methods that provide lasting protection against corrosion, improved mechanical properties and an aesthetically pleasing appearance to the components.

What sets us apart?

We are the market leader with our on-time delivery and unique customer service, based on a personalised approach and advanced technology consultation.

Porsonalised approach to the customer

We get involved in every project, tailoring our services to the specific needs of our customers. Our approach is based on a thorough understanding of your expectations. We combine these with our experience, ensuring that we always achieve the desired results.

Short lead time

At Foseko, you don’t have to wait weeks for your order to be completed. Our paint shop is a modern and comprehensive powder coating centre, where we have been applying protective and decorative coatings to metal components for years. We have a modern line and professional service.

Modern technology

We use innovative solutions from renowned manufacturers such as Wagner, Lechler, Bosch-Rexroth, Ferroli, Eurowater and Fatek. We have a specialised heat property recorder and paint thickness gauges. We use tried and tested products and solutions.

Surface preparation

We attach great importance to careful preparation of the surface, both mechanically and chemically. This ensures that our coatings are of the highest durability and quality. The surface preparation process is key to achieving excellent results.

Weather resistance

Powder coatings made in our paint shop are extremely durable and weatherproof. This makes them ideal for industrial and architectural applications. They are a guarantee of long-term protection and aesthetic look of your products.

Comprehensive service

We offer a full range of services, including securing and preparing finished products for transport. We make sure that your order arrives in perfect condition. Our team monitors the whole logistics process, ensuring timely and smooth delivery.

Such a large-scale output is proof of well-established processes and consistent quality — no matter the size of the order.

Hundreds of companies across various industries have trusted us — we know how to tailor technology to each project’s unique needs.

With decades of hands-on practice, we combine expertise with modern solutions to deliver durable and visually refined coatings.

See our projects

Find out how our actions translate into customer results.

Team

With us, there is no room for coincidence. At Foseko, we are professionals with many years of experience in the industry.

Aleksander Przyborski Coating Plant Manager

He manages key production and sales processes, ensuring smooth plant operations and the development of customer relationships. He specializes in process planning and optimization to deliver solutions that meet the highest industry standards.

Marek Siembida Production Manager

He is responsible for order execution and overseeing production, ensuring efficient processes and quality control at every stage. He focuses on a well-trained team and continuous improvement of technology to achieve consistent, high-quality results.

Sebastian Sokołowski Owner

He ensures the highest quality of powder coatings by investing in modern technologies and precise surface preparation processes. He supports clients with technological consulting, helping them choose the best solutions for durability and aesthetics.

Opinie

Find out what our customers are saying

Piotr Bąk

Deputy Head of Procurement

We are very satisfied with our cooperation with FOSEKO and would confidently recommend working with such a professional company.

Fast communication, express service execution, and full professionalism truly set this company apart in the market. We highly recommend them.

Jakub Bober

CEO

Years of cooperation with FOSEKO allow us to confidently state that this is a reliable and trustworthy company that approaches each order with full professionalism. We can always count on fast order fulfillment and expert advice.

Tomasz Stafij

Planning Manager at Kospel Sp. z o.o.

We are extremely satisfied with the services provided by Foseko. Their professionalism and attention to detail ensure that every project is completed to the highest standard. Cooperation with them is always smooth and on time. We highly recommend Foseko as a reliable partner in the coating industry.

Przemysław Madejski

A very professional company. I am a regular customer and always gladly return. They provide expert advice and excellent workmanship.

Arek Hlobil

I’ve been working with this company for over six months. Complete professionalism. Everything is delivered on time and according to the agreement. Highly recommend.

Michal Zdanowicz

Fast service execution and reasonable prices. Highly recommend!

Dariusz Lewandowski

Managing Director

As the Managing Director of Inter-Metal s.c., I would like to express our complete satisfaction with our cooperation with Foseko, which has been providing us with powder coating services for around 10 years.

Over the years, working with Foseko has brought us many benefits. The company has successfully resolved numerous logistical challenges we encountered in this area (…)

Talk to an expert

Do you need professional advice? Fill in the contact form and our representative will get in touch with you.

Aleksander Przyborski

Pracujemy z firmami z Polski oraz zachodniej i północnej Europy. Lokalnie obsługujemy klientów między innymi z:

- Bydgoszcz

- Chojnice

- Gdańsk

- Gdynia

- Gorzów Wielkopolski

- Grudziądz

- Inowrocław

- Kołobrzeg

- Koszalin

- Lębork

- Piła

- Poznań

- Słupsk

- Szczecin

- Świnoujście

- Toruń

Below you will find the answers to the most frequently asked questions

Are we suitable for large-scale painting?

No, Foseko specialises in painting metal components of standard dimensions. We focus on the precise application of protective and decorative coatings using advanced technology and equipment. We focus on the precise application of protective and decorative coatings using advanced technology and equipment.

What comprises the surface preparation process?

Surface preparation is carried out using two methods: Mechanical: Includes shotblasting or glass bead blasting to ensure adequate paint adhesion.

Mechanical: Includes shotblasting or glass bead blasting to ensure adequate paint adhesion.

Chemical: We use proven Elhus chemicals to effectively clean and degrease surfaces.

What is our paint application process? Is it electrostatic?

Yes, we use electrostatic technology. This allows the paint to adhere evenly to the surface, minimising material loss and ensuring the highest quality finish.

What agents do we use for degreasing?

To degrease the surface, we use Elhus chemicals, which effectively remove all contaminants, preparing the components for the subsequent painting process.

What machines do we use for powder spraying?

Do we help with the RAL colour selection process?

Yes, upon request we can help you choose the right RAL colours, taking into account the specifics of your order and your aesthetic preferences.

What do we use to cure the painted surface?

No additional curing agents are used in the powder coating process.

Powder paints require curing in a specialised oven, which guarantees durability and resistance of the coating.